Inkampani yethu ikhiphe ngokusemthethweni isiteshi sezulu esisha se-aluminium alloy. Lesi siteshi sezulu, esinokuqina okuhle kakhulu, esilula futhi esinokunemba okuphezulu, sidonsele ukunaka okukhulu emphakathini wesimo sezulu kanye nezinhlangano zemvelo.

Umklamo omusha kanye nokusetshenziswa kwezinto ezibonakalayo

Okugqamile kakhulu kulesi siteshi esisha sezulu ukuthi sisebenzisa i-aluminium alloy enamandla aphezulu njengezinto zokwakha eziyinhloko. I-aluminium alloy ayigcini nje ngokuba nokumelana okuhle kakhulu nokugqwala kanye nokumelana nomoya, kodwa futhi inciphisa kakhulu isisindo semishini iyonke. Uma kuqhathaniswa neziteshi zesimo sezulu zendabuko, isisindo sesiteshi sezulu se-aluminium alloy sincishiswa cishe ngo-30%, okwenza kube lula kakhulu ngesikhathi sokuthuthwa nokufakwa.

1. Ukumelana nokugqwala:

Izinto ze-aluminium alloy zinokumelana nokugqwala kwemvelo, ngisho nasezindaweni ezisogwini noma endaweni enomswakama ophezulu, zingagcina isimo sokusebenza esizinzile isikhathi eside. Lokhu kubalulekile ukuze idatha yesimo sezulu iqhubeke futhi inembile.

2. Ukumelana nomoya:

Ngobunjiniyela obunembile kanye nokukhethwa kwezinto, isiteshi sezulu se-aluminium alloy siyakwazi ukumelana nesivinini somoya esifinyelela kumakhilomitha angu-200 ngehora, okuqinisekisa ukusebenza okuvamile ezimweni zezulu ezimbi kakhulu.

3. Ilula:

Ukusetshenziswa kwe-aluminium alloy kwenza isisindo sonke sesiteshi sezulu sibe phansi kakhulu, okungagcini nje ngokunciphisa izindleko zokuhamba, kodwa futhi kunciphisa nomthelela emvelweni ngesikhathi sokufakwa.

Ukuqapha okunembile okuphezulu kanye nomsebenzi ohlakaniphile

Ngaphezu kokusungula izinto ezintsha, lesi siteshi sezulu se-aluminium alloy siphinde sathola impumelelo enkulu ekuqapheni ubuchwepheshe kanye nemisebenzi ehlakaniphile.

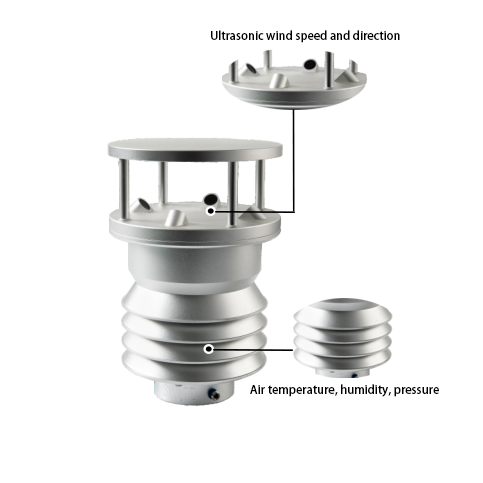

1. Inzwa yokunemba okuphezulu:

Isiteshi sezulu sihlonyiswe ngesizukulwane sakamuva sezinzwa ezinembile kakhulu ezingaqapha izinga lokushisa, umswakama, umfutho womoya, isivinini somoya, isiqondiso somoya, imvula, imisebe yelanga kanye nezinye izilinganiso zesimo sezulu ngesikhathi sangempela. Lezi zinzwa zisebenzisa ubuchwepheshe obuthuthukisiwe besistimu ye-microelectromechanical (MEMS) ukuqinisekisa ukunemba kwedatha nokuthembeka kwayo.

2. Ukudluliswa kwedatha ngesikhathi sangempela:

Isiteshi sezulu sinemojuli ye-Internet of Things (IoT) eyakhelwe ngaphakathi edlulisela idatha yesikhathi sangempela epulatifomu yamafu ngenethiwekhi engenantambo. Lokhu kuvumela izazi zezulu namaqembu ezemvelo ukufinyelela ulwazi lwakamuva lwesimo sezulu noma nini, noma kuphi ukusekela ukwenza izinqumo.

3. Ukuhlaziywa okuhlakaniphile kanye nesixwayiso sangaphambi kwesikhathi:

Ngokusekelwe ku-cloud computing kanye nobuchwepheshe bokuhlaziya idatha enkulu, iziteshi zesimo sezulu ziyakwazi ukwenza ukuhlaziywa okuhlakaniphile kwedatha eqoqwe futhi zikhiqize ulwazi lwesixwayiso ngesikhathi sangempela. Isibonelo, lapho kubikezelwa izenzakalo zesimo sezulu esibi kakhulu, uhlelo luxwayisa ngokuzenzakalelayo izinhlangano ezifanele kanye nomphakathi ukuthi bathathe izinyathelo zokuphepha ezidingekayo.

Izimo zokusetshenziswa kanye nezinzuzo zezomnotho

Lesi siteshi sezulu se-aluminium alloy sifanelekela izimo ezahlukahlukene zokusetshenziswa, okuhlanganisa ukuqaphelwa kwesimo sezulu, ukuqapha imvelo, ukuphathwa kwezolimo, isixwayiso senhlekelele njalo njalo. Izici zaso ezilula neziqinile zenza sifaneleke kakhulu ukusetshenziswa ezindaweni ezikude nasezindaweni ezinzima.

1. Ukuqaphelwa kwesimo sezulu:

Kunethiwekhi yokubuka isimo sezulu, iziteshi zesimo sezulu ze-aluminium alloy zinganikeza idatha yesimo sezulu eqhubekayo nenembile, enikeza ukwesekwa okubalulekile kokubikezela isimo sezulu kanye nocwaningo lwesimo sezulu.

2. Ukuqapha imvelo:

Kumaphrojekthi okuqapha imvelo, iziteshi zesimo sezulu zingaqapha ikhwalithi yomoya, ukungcoliswa komsindo kanye nezinye izilinganiso ukuze kunikezwe isisekelo sokwakhiwa kwenqubomgomo yezemvelo.

3. Ukuphathwa Kwezolimo:

Kwezolimo, iziteshi zezulu zinganikeza idatha yesimo sezulu enembile ukusiza abalimi ukuthuthukisa izinhlelo zokutshala nokwandisa isivuno sezitshalo.

4. Isexwayiso senhlekelele:

Ngokuphathelene nesixwayiso senhlekelele kusenesikhathi, iziteshi zesimo sezulu zingaqapha imingcele yesimo sezulu ngesikhathi sangempela futhi zikhiphe izixwayiso kusenesikhathi lapho izenzakalo zenhlekelele zibikezelwa ukuthi zizonciphisa ukulahlekelwa okubangelwa yizinhlekelele.

Isazi sesimo sezulu uDkt. Emily Carter siphawule: “Ukusungulwa kwesiteshi ezintweni zokwakha kanye nobuchwepheshe kwenza sikwazi ukugcina ukunemba okuphezulu ezimweni zezulu ezimbi kakhulu, okubalulekile ekuthuthukiseni ukunemba kwezibikezelo zesimo sezulu.”

UTom Williams, ummeleli womsebenzisi kanye nenhloko yenhlangano yezolimo, uthe: “Besilokhu sifuna isiteshi sezulu esinembile kakhulu esingasebenza kahle ezindaweni ezinzima, futhi lesi siteshi sezulu se-aluminium alloy sifanelana kahle nezidingo zethu. Akulula nje kuphela ukusifaka, kodwa futhi sinikeza idatha yesimo sezulu eqhubekayo nenembile, enikeza ukwesekwa okubalulekile ekukhiqizweni kwethu kwezolimo.”

Ukufika kwesiteshi esisha sezulu se-aluminium alloy kubonisa ukuthi ubuchwepheshe bokuqapha isimo sezulu bungene enkathini entsha. Ukusungula izinto ezintsha, ukuklama kanye nemisebenzi kunikeza izixazululo ezithembeke kakhulu ezindaweni ezifana nokubuka isimo sezulu, ukuqapha imvelo, ukuphathwa kwezolimo kanye nokuxwayisa ngenhlekelele. Esikhathini esizayo, ngentuthuko eqhubekayo yobuchwepheshe kanye nokwanda kwezimo zokusetshenziswa, iziteshi zesimo sezulu ze-aluminium alloy zizodlala indima ebalulekile emikhakheni eminingi futhi zifake isandla ekwakhiweni kwendawo engcono yemvelo.

Ukuze uthole ulwazi olwengeziwe ngesiteshi sezulu,

sicela uxhumane ne-Honde Technology Co., LTD.

Email: info@hondetech.com

Iwebhusayithi yenkampani:www.hondetechco.com

Isikhathi sokuthunyelwe: Jan-14-2025